Description

Video above: Roller Engraving

Roller engraving on glass is derived from hard rock engraving. It was used as early as the Roman period in the 4th and 5th centuries AD. In modern times, is was used in Prague between the end of the 16th century and the beginning of the 17th century. From here it spread everywhere.

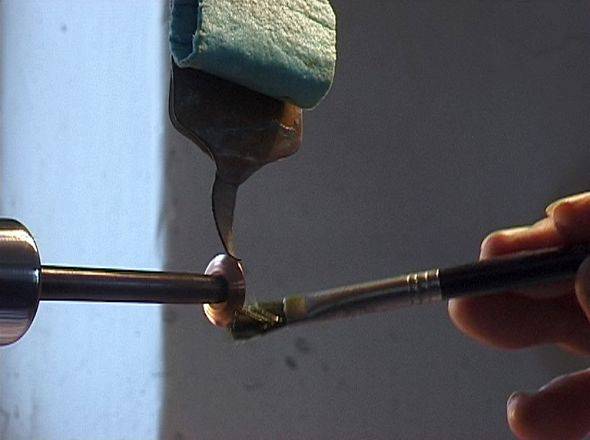

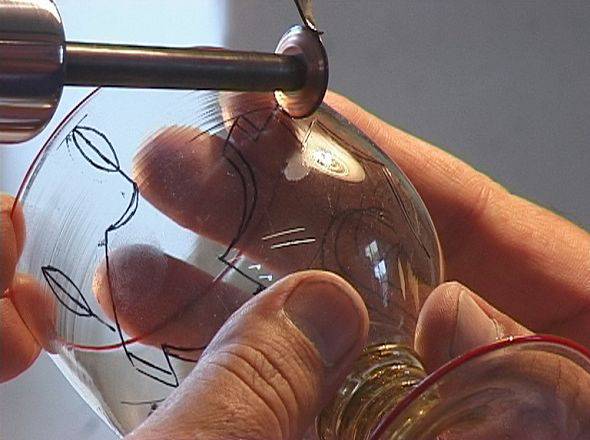

The engravings are carried out by a vertical copper wheel, which varies in thickness and size, welded onto a lathe, once powered by pedals and nowadays by an electric motor. A flexible brass tape, at the end of which a leather tongue is attached, disperses an oily suspension of abrasive powder onto the surface of the outline of the roller, which nowadays is silicone carbide (carborundum) or corundum carbide. The deepest engravings can be obtained with a stone wheel. Polishing is generally carried out with a cork roller.

The engravings can be made deeply (cutting) with superimposed engravings which create a bas-relief optical effect or a relief one on thick glass, by lowering the glass surface with the engravings in relation to the background.

The most suitable glass for engraving is lead crystal, which is finely crumbled by the tool, with a resulting engraving which is neater and more exact.