Description

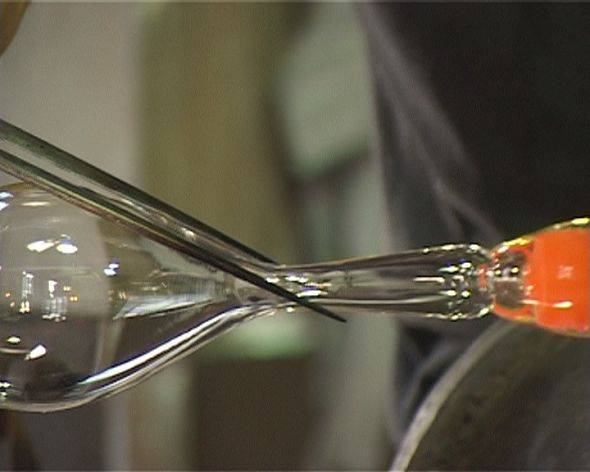

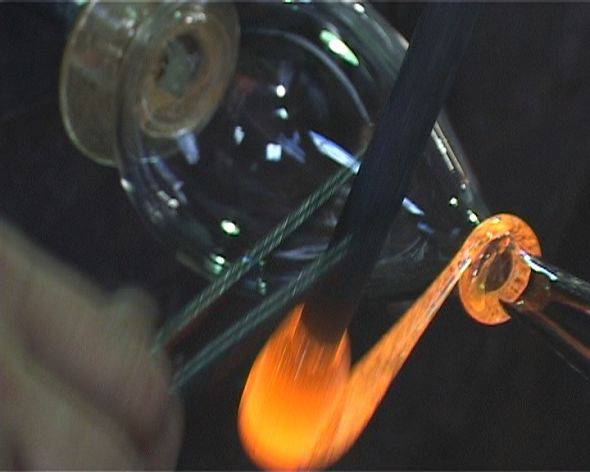

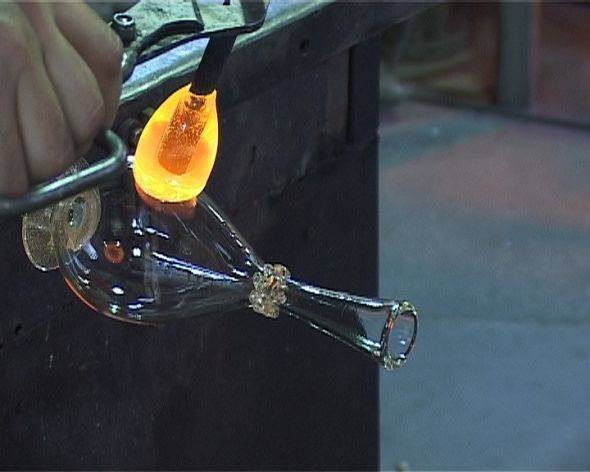

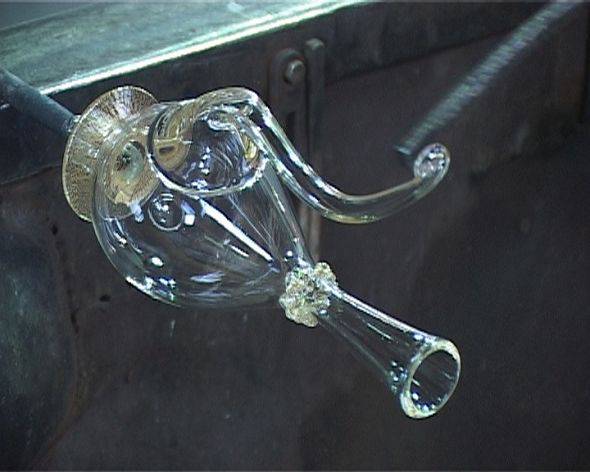

Hollow ware applications are obtained by starting with a good-sized gob of glass attached to the wall of the mould. While the gobs are incandescent, the glassworker blows inside the object, it expands towards outwards, it is filled with air and it becomes hollow. The glassworker then stretches the ends with calipers and models them to his liking. A well known Franco medieval type, for example, has the claw beacher decoration.

Interior hollow ware applications are obtained by good-sized glass gobs attached to the wall of a blown object attached to a blow pipe. By blowing through the blow pipe, the incandescent glass of the gobs pulls into the inside thereby forming a bubble. Many types were worked like this in the past, like Daumenglas (thumb glass) produced in Germany and in the Netherlands in the 16th-17th century.